Why Warehouses and Logistics Companies Need EOT Cranes: A Complete Guide for Modern Material Handling

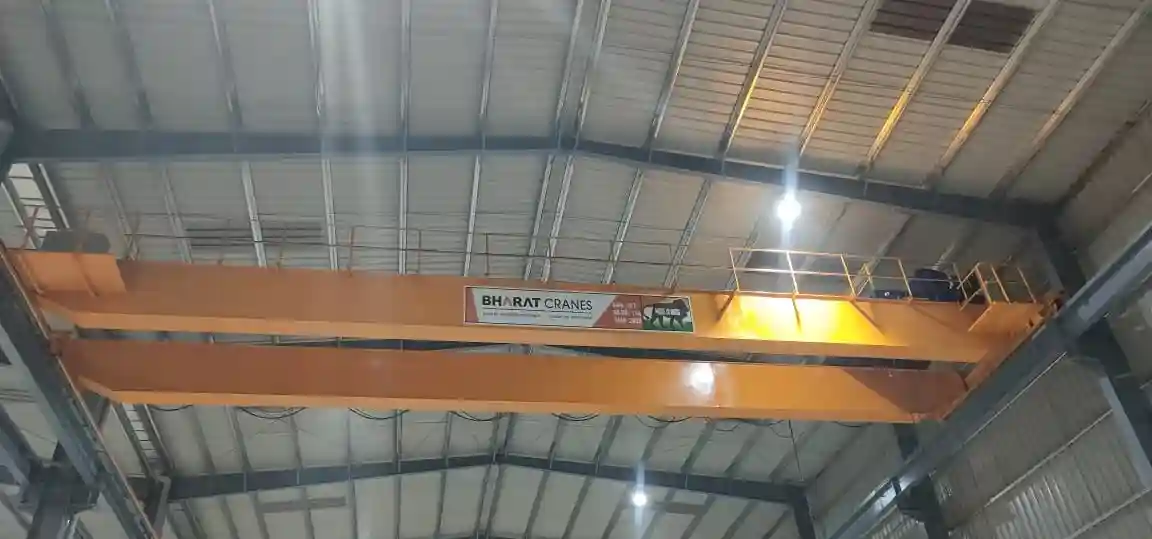

In today’s fast-moving supply chain landscape, warehouses and logistics companies are under constant pressure to deliver higher productivity, faster turnaround, and flawless operational efficiency. From e-commerce fulfilment centres and 3PL hubs to distribution warehouses and cold-storage facilities, the demand for robust, reliable, and intelligent material handling systems is rising every single year. While forklifts, pallet trucks, conveyors, and automated storage systems play their roles, one equipment stands out when it comes to lifting, shifting, and handling heavy loads with precision—the EOT (Electric Overhead Travelling) Crane.

EOT cranes have emerged as a core asset for modern warehouses and logistics companies due to their ability to enhance efficiency, reduce human effort, optimize space, and ensure safe movement of goods. They provide indoor lifting solutions that are not only economical but also highly reliable, customizable, and capable of handling a wide range of material weights and dimensions. Whether it’s handling pallets, stacking inventory, feeding production lines, supporting outbound logistics, or moving heavy equipment inside a facility, EOT cranes bring a new dimension of control and adaptability to warehouse operations.

This blog explores in depth why EOT cranes have become essential for warehouses and logistics companies, how they transform operations, and what benefits they provide from a safety, efficiency, and cost-saving perspective.

Understanding the Role of EOT Cranes in Warehousing and Logistics

EOT cranes operate on parallel runways with a travelling bridge across the gap. The hoist moves along the bridge, allowing the crane to lift and transport loads effortlessly across the entire workspace. In warehouse and logistics operations, where space, efficiency, and safety are critical, this design offers enormous advantages.

Unlike ground-based material handling equipment such as forklifts or pallet trolleys, an EOT crane uses unused overhead space, making movement efficient and clutter-free. It seamlessly covers large areas of the warehouse without interrupting workflow on the shop floor. With a wide variety of capacities—from light-duty single girder cranes to heavy-duty double girder systems—EOT cranes prove helpful in everything from handling automation machinery to managing bulky loads like containers, dies, moulds, pallets, coils, assemblies, and large inventory items./p>

As warehouses expand, adopt automation, and move toward Industry 4.0, the demand for overhead lifting systems is becoming even more critical.

EOT Cranes Help Warehouses Maximise Their Vertical Space

One of the biggest constraints in warehouses is floor space. As product volumes increase and SKU variety grows, companies struggle to store more in the same footprint. Ground equipment such as forklifts cannot always reach high levels or navigate tightly packed racks. EOT cranes, however, utilize vertical and overhead space effectively.

They allow smooth load movement high above the ground, which:

- Frees up floor area for additional racking or movement

- Allows operators to lift, place, or retrieve goods from elevated locations

- Reduces congestion and improves movement pathways

- Supports better warehouse layout and space planning

By making overhead space usable, EOT cranes enable warehouses to scale operations without expanding their physical infrastructure.

Improved Safety in Material Handling Operations

Warehousing and logistics involve constant movement of goods—often bulky, awkwardly shaped, or heavy. Manual lifting or forklift-based movement can lead to safety risks. Incorrect pallet stacking, operator errors, and narrow aisle navigation are common accident triggers.

EOT cranes significantly reduce these risks by offering controlled, precise, and stable load handling.

Key safety benefits include:

- Smooth hoist movement prevents load swing

- Radio remote or pendant control keeps operators at a safe distance

- Advanced brakes ensure instant stopping li>Anti-collision devices prevent crane-to-crane or crane-to-structure damage

- Overload protection prevents unsafe lifting

By enabling safe vertical lifting and controlled travel paths, EOT cranes protect both goods and workers while reducing accident-related downtime.

Increasing Warehouse Productivity and Turnaround Speed

Speed is critical in logistics. Whether it’s inbound unloading or outbound dispatch, quick material movement determines the overall cycle time. EOT cranes excel in performing repetitive lifting and shifting tasks faster than manual or forklift operations.

How EOT cranes improve productivity:

- Deliver consistent lifting speed and smooth acceleration

- Reduce time spent manoeuvring through aisles

- Ensure continuous movement across the entire warehouse width

- Can be operated by a single operator

- Allow simultaneous tasks when two cranes work in tandem

For high-volume logistics hubs like e-commerce, retail distribution, FMCG warehouses, and industrial storage facilities, this improvement in operational speed translates into higher customer satisfaction and competitive advantage.

Cost Efficiency and Better Long-Term ROI

Investing in an EOT crane may seem capital-intensive, but warehouses gain significant long-term savings.

Direct financial benefits include:

- Reduced dependence on multiple forklifts

- Lower fuel and maintenance costs compared to diesel-driven equipment

- Minimal labour involvement

- Longer service life with low upkeep requirements

- Reduced damage to goods during handling

EOT cranes also bring operational consistency, which minimizes downtime and ensures smoother workflows. Most importantly, they reduce labour costs and enhance the efficiency of every shift—delivering an ROI that continues for years.

Ideal for Handling Bulky and Heavy Loads

Logistics isn’t only about moving boxes or pallets. Many warehouses store:

- Machinery

- Tooling equipment

- Coils or sheets

- Large raw materials

- Packaging rolls

- Industrial components

- Containers

- Assemblies

These items are difficult or unsafe to move using forklifts. EOT cranes provide the strength and stability needed to lift and relocate such heavy loads effortlessly. With capacities ranging from 1 Ton to 100+ Tons, warehouses and logistics hubs choose the crane capacity based on their inventory profile or incoming/outgoing shipment needs.

Enhancing Automation and Smart Warehousing

Modern warehouses are moving toward automation. Integrating EOT cranes with digital systems enables:

- Automated material transfers

- Sensor-based positioning

- RFID tracking

- Barcode-triggered lifting instructions

- Real-time load monitoring

- Centralised crane fleet management

With IoT-enabled remote crane monitoring, warehouse managers can track crane health, utilisation, load cycles, and operational hours, helping plan maintenance proactively. This aligns perfectly with smart logistics operations and Industry 4.0 goals.

Reducing Ground Traffic and Congestion

A warehouse filled with moving forklifts can quickly become chaotic. Ground traffic increases risks, reduces space efficiency, and slows down material flow.

EOT cranes solve this by:

- Taking lifting operations off the floor

- Creating cleaner pathways for employees and other equipment

- Allowing seamless movement above crowded areas

- Avoiding forklift bottlenecks in narrow aisles

This leads to smoother traffic flow inside the warehouse and increased operational discipline.

Versatility Across Multiple Warehouse Operations

EOT cranes support a wide variety of tasks across warehouse and logistics setups, such as:

- Inbound Operations

- Unloading goods

- Placing materials on pallets or racks

- Feeding incoming materials to sorting areas

- Inventory Management

- Moving oversized goods for storage

- Relocating heavy or palletized stock

- Supporting cycle counting and warehousing audits

- Outbound Operations

- Loading goods for dispatch

- Positioning loads for final shipment preparation

- Internal Reallocation

- Supporting maintenance tasks

- Handling repair parts or spares inventory

- Moving inventory between sections

This versatility makes EOT cranes indispensable for both small and large warehouses.

Customizable to Suit Warehouse Layouts

No two warehouses are alike. Layout, height, storage systems, and workflow patterns differ across industries. EOT cranes can be customised accordingly:

- Single Girder EOT Crane for light to medium duties

- Double Girder EOT Crane for heavy loads

- Underslung Crane for low-headroom warehouses

- Gantry or Semi-Gantry Cranes for indoor-outdoor movement

- Monorail Cranes for dedicated paths

- KBK Light Crane System for flexible, lightweight operations

This customization makes them adaptable to any warehouse environment.

Supporting Expansion Without Additional Construction

As product volumes grow, companies often consider expanding their warehouse size. However, civil expansion is expensive and time-consuming.

EOT cranes help avoid or delay such expansion by:

- Maximizing existing floor and vertical space

- Improving operational speed

- Reducing clutter

- Allowing more inventory to be stored efficiently

By optimizing the facility’s internal layout and handling capacity, warehouses achieve more productivity using the same infrastructure.

Reduced Wear and Tear on Goods

Forklifts and manual handling increase the risk of product damage due to:

- Improper lifting angles

- Tilting

- Sudden jerks

- Collisions

- Human error

With EOT cranes, loads are lifted vertically and moved horizontally in a controlled manner, reducing:

- Scratches

- Dents

- Breakages

- Packaging damage

This is especially crucial for warehouses handling delicate, high-value, or bulky goods.

Essential for High-Bay Warehouses

High-bay warehouses need advanced lifting systems to handle tall racking structures with precision. EOT cranes are ideal for such environments because:

- They can reach and operate at great heights

- They offer high lifting speeds

- They ensure stable placement of goods

Whether it’s cold storage, e-commerce fulfilment, or industrial spares warehousing, high-bay facilities increasingly adopt overhead crane systems.

Conclusion: EOT Cranes Are No Longer Optional—they are Essential for Modern Warehousing and Logistics

The warehousing and logistics sector is evolving rapidly, with higher customer expectations, faster delivery promises, and increasing SKU volumes. In this environment, businesses can no longer rely solely on ground-based material handling equipment.

EOT cranes offer a perfect blend of:

- Efficiency

- Safety

- Space optimisation

- Speed

- Cost savings

- Scalability

- Automation compatibility

As warehouses continue shifting toward smarter, more flexible operations, adopting EOT cranes becomes not just a choice but a strategic necessity. For companies aiming to upgrade their material handling system, enhance safety, and boost productivity, an EOT crane is one of the most impactful investments.