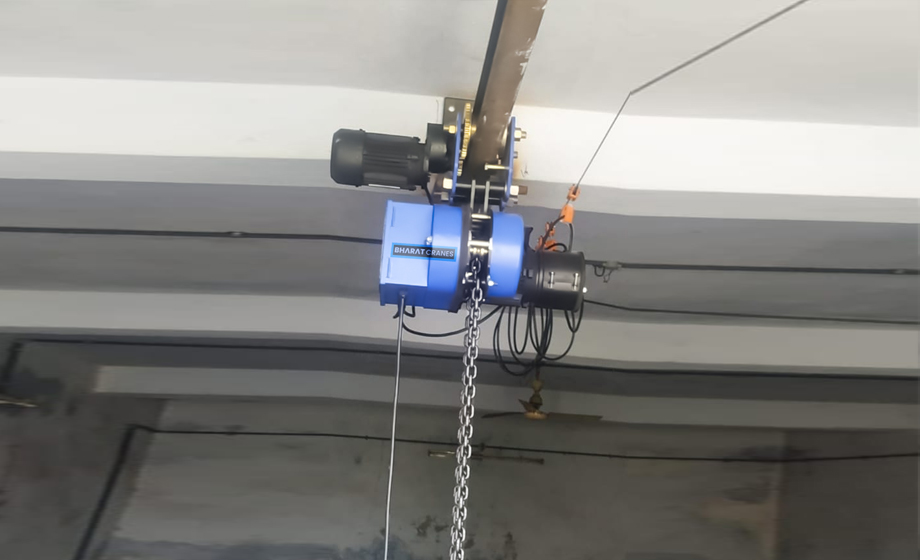

We are one of the trusted electric hoist manufacturers in Pune, offering reliable and efficient lifting solutions for industrial use. Our electric hoists are manufactured to handle daily lifting operations safely and smoothly in factories, workshops, and industrial plants. With our manufacturing unit in Pune and a strong supply network, we also serve customers across the country, making us a dependable choice among electric hoist manufacturers in India.

Electric Hoist Manufacturers in Pune

Electric Hoist Manufacturers in India

As experienced electric hoist manufacturers in India, we focus on manufacturing hoists that are easy to operate, durable, and suitable for various industrial applications. Our electric hoists are designed to support material handling needs where accuracy and safety are important. Each hoist is manufactured with quality components and tested to ensure consistent performance in demanding working conditions.

From Pune, we supply electric hoists to different parts of India, supporting industries that require dependable lifting equipment for their daily operations.

Electric Chain Hoist Manufacturer in India

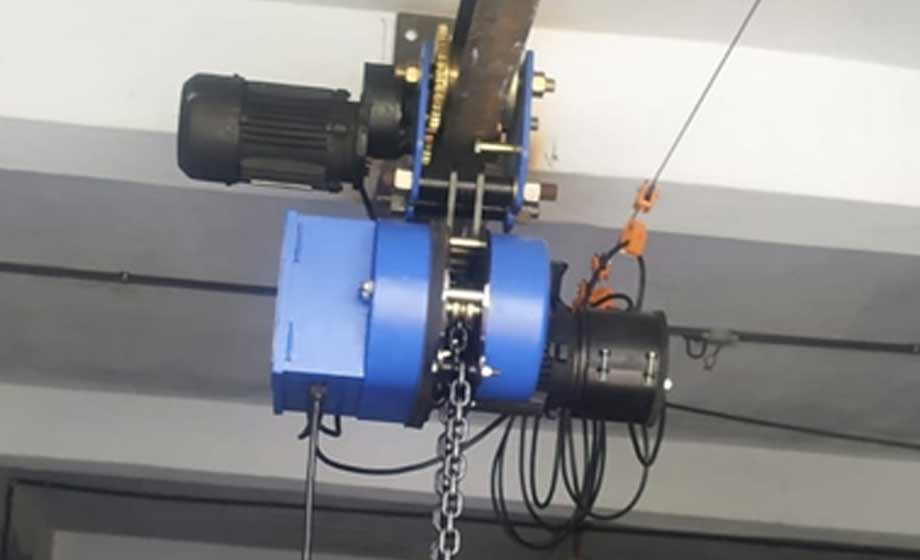

We are also a reliable electric chain hoist manufacturer in India, providing electric chain hoists that offer smooth lifting and controlled movement of loads. These hoists are suitable for use with EOT cranes, gantry cranes, jib cranes, and monorail systems. Our electric chain hoists are manufactured to support precise lifting while maintaining safety and efficiency in industrial environments.

Industries across India trust our electric chain hoists for their stable performance and long service life.

Why Choose Us for Electric Hoists

Being based in Pune allows us to understand the requirements of local industries while also serving customers across India. We focus on manufacturing electric hoists that are practical, reliable, and suited for real working conditions. Our team works closely with clients to understand their lifting needs and provide suitable electric hoist solutions.

Our commitment to quality, timely delivery, and customer support has helped us build long-term relationships with industrial customers looking for dependable electric hoist manufacturers in Pune and India.

Applications of Electric Hoists

Our electric hoists are commonly used in manufacturing units, assembly lines, warehouses, fabrication shops, engineering industries, and material handling areas. They help in lifting and positioning loads efficiently, improving productivity and safety at the workplace. Electric chain hoists are especially useful where controlled lifting and smooth operation are required.

Supply Across India from Pune

With our manufacturing base in Pune, we supply electric hoists and electric chain hoists to customers across India. We ensure proper coordination and technical guidance so that our hoists are installed and used effectively. This pan-India supply capability strengthens our position as reliable electric hoist manufacturers in India.

-

Compact Design: Space-saving design with a robust and durable body. High Lifting Capacity: Available in various models with lifting capacities ranging from 500 kg to several tons.

-

Smooth Operation: Equipped with a precision gear system for smooth and quiet operation.

-

Variable Speed Control: Offers multiple speed settings for precise lifting and positioning.

-

Safety Mechanisms: Integrated with overload protection, emergency stop button, and upper/lower limit switches.

-

Energy Efficiency: Designed to consume less power while providing maximum efficiency.

-

Low Maintenance: Requires minimal maintenance due to its simple and sturdy construction. Customizable Options: Available with options for dual-speed operation, radio remote control, and more.

-

Load Capacity: Up to 20 tons

-

Lift Speed: Variable speeds depending on model

-

Lift Height: Up to 50 meters

-

Control: Pendant or remote control

-

Applications: Assembly lines, workshops, maintenance facilities

-

Manufacturing Plants: Ideal for lifting and moving heavy machinery and components.

-

Warehousing: Used for handling goods and materials in storage facilities.

-

Construction Sites: Perfect for lifting construction materials and equipment.

-

Automotive Industry: Suitable for assembly line tasks and heavy-duty lifting.

-

Shipyards: Utilized for loading and unloading heavy ship parts and materials.

-

Aerospace: Employed in handling aircraft components during assembly.

-

Mining Operations: Essential for moving large and heavy mining equipment. Steel Mills: Used for lifting and handling steel coils, plates, and other materials.

-

High Load Capacity: Capable of lifting and moving heavy loads with ease, suitable for demanding industrial applications.

-

Precision Control: Offers precise control over lifting and lowering operations, ensuring accurate placement of materials.

-

Compact Design: Space-saving design allows for installation in areas with limited headroom or restricted space.

-

Durability: Built to withstand harsh working environments and heavy usage, providing long-term reliability.

-

Ease of Use: Simple controls and user-friendly operation make it accessible for operators with varying levels of experience.

-

Low Maintenance: Fewer moving parts compared to manual hoists, reducing maintenance needs and associated costs.

-

Energy Efficiency: Operates efficiently, reducing power consumption compared to older or manual lifting systems.

-

Safety Features: Equipped with safety mechanisms such as overload protection and emergency stop functions to prevent accidents.