What Is a Crane Crab?

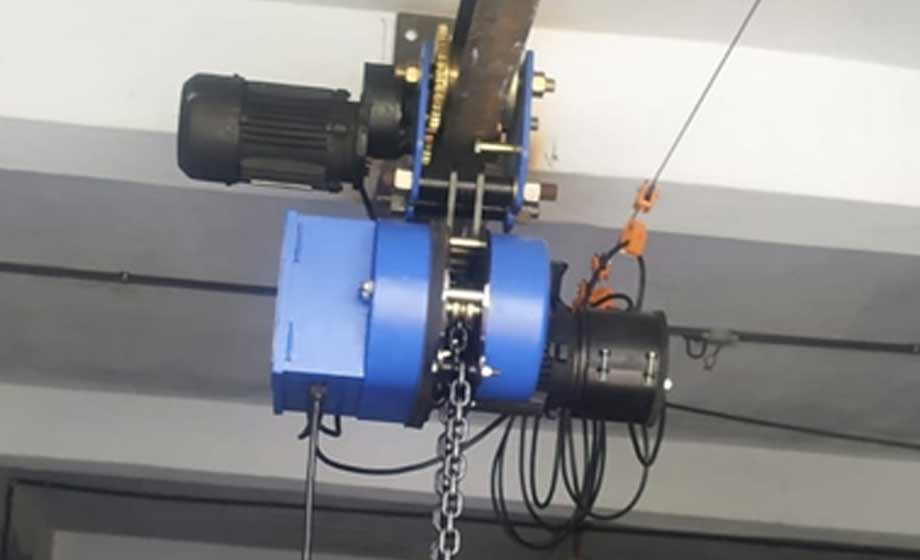

A crane crab is the movable hoisting unit mounted on the bridge of an overhead crane. It carries the hoist mechanism and travels along the crane girder, enabling controlled lifting and horizontal movement of loads. The crab in crane assembly plays a critical role in ensuring safe, stable, and efficient material handling operations.

Crane and Crab System for Overhead Cranes

The crane and crab system works together to provide complete lifting functionality. While the crane structure supports and guides movement, the crab unit performs the actual lifting and cross travel. Our crane crab designs are compatible with single girder and double girder EOT cranes and can be customized to suit specific load capacities, spans, and duty cycles.

Role of Crab in Crane for Industrial Material Handling

The crab in crane is responsible for accurate positioning of loads within the working area. A well-designed crane crab ensures smooth acceleration, controlled braking, and minimal vibration during lifting operations. This results in improved safety, reduced wear on components, and higher productivity on the shop floor.

Our Crane Crab Manufacturing Capabilities

As an experienced crane crab manufacturer in Pune, we focus on precision engineering, robust construction, and compliance with industry standards. Each crane crab is manufactured using high-grade materials and tested for performance, safety, and durability before dispatch. Our in-house design and manufacturing capabilities allow us to deliver reliable crane crab solutions for a wide range of industrial applications.

Why Choose Us as Your Crane Crab Manufacturer?

We understand the importance of dependable lifting equipment in industrial operations. Our focus on quality manufacturing, technical expertise, and customer-oriented solutions makes us a trusted partner for crane crab systems. From standard designs to customized requirements, we deliver crane crabs that support safe and efficient material handling.